Late April reminds you why it is the cruelest month. Taxes and lawns. Taxes and lawns. You know, the neighbourhood’s lawns may look a bit crap because people can’t figure out and if the “No Mow May” thing applies (i) up to and including May or (ii) just during May. Me, I am just lazy. See, I have one of those whirly manual mowers that doesn’t cut so good so it takes five times longer than it should and leaves me beat. What’s new this year, however, is news that “No Mow May” might actually be bad for bees! Apparently it’s like feeding your children by leaving hard candies around the yard. Not sure how that fits into my lazy plan… but I’m working on it. That’s my Grandfather up there, by the way, out with the lads about a century ago when he was in his twenties. Second from the right. In case it isn’t obvious to one and all, his name was Jimmy.

Speaking of the crop to come, I wondered to myself when I saw this report in the Western Producer on the forecasts for the next Canadian barley harvest:

Canadian barley supplies are likely to be burdensome in 2024-25, according to a market outlook published by the Saskatchewan Barley Development Commission. Supplies are forecast to be in the range of 10.7 to 11.7 million tonnes. “This is well above the 2023-24 supplies at 9.65 million tonnes and the five-year average of 10.3 million,” stated the report authored by LeftField Commodity Research.

Last time I heard the word “burdensome” used like that was when I was eight years old and asked too many questions about the rules of the hockey as Dad was trying to watch an NHL playoff game on a snowy black and white TV. Seems the language of barley forecasting is all rather ripe. We read “…lower prices combined with poor movement have cast a shadow…” and “…supplies will be bloated…” as well as “…France has got some problems…”

While we are on the subject of brewing malts, Matty C has been busy scribbling away and shared his story “How British Heritage Malts Are Making a Comeback” at CB&B starting with the tale of one particular ale:

That grist includes small portions of amber, black, brown, and chocolate malts—each about 5 percent of the bill. The most significant twist, however, is that McKenzie replaces 20 percent of the pale base with malt made from a specialty heritage barley variety known as Chevallier, produced by Crisp Malt of Great Ryburgh, Norfolk, in the east of England. A two-row, narrow-eared variety, Chevallier dominated barley farming in England throughout the 19th and early 20th centuries, beginning to fall out of favor about 1920. By 1940, production of Chevallier had ceased. In 2017, however—after four years of small-batch trials—Crisp commercially released a five-ton batch produced at its traditional floor maltings at its headquarters in the east of England. At RedWillow, McKenzie was one of the first brewers to get to play with it.

Sounds good – but bring me my Battledore Porter and I’ll be right in there. Speaking of wishes come true, NHS Martin moved beyond the boundaries of mere beer when he and she explored a rather empty Sophia, the capital of Bulgaria, this week:

Blimey. 9 million in 1985 before Communism crumbled; 6.5 million and falling now. And further Googling revealed plenty of commentary on the ageing and depopulation of Bulgaria, the result of migration, falling birth rates (1.6, same as UK) and the sporadic availability of London Pride on hand pump. It had certainly felt “spacious” on our night out, and though those craft beer bars we’d visited were busy enough I guess there’s your warning about judging a place by its craft beer bars.

Speaking of wandering worldly ways, the Tand has been considering the pubs of Oz and found one away from the tour group that made his day, The Exeter Hotel in Adelaide:*

…we found ourselves in a proper public bar, with a central bar serving the room we were in and another room opposite. It was basic, unspoilt with wooden floors, a few bar stools, a handful of characterful locals and a couple of rather fearsome women serving. We immediately knew we were in safe hands. It was stunningly good. Even on a warm Adelaide night, indoors here was way preferable. This was smashing. It turned out to be a Cooper’s of Adelaide tied house, with a reasonable number of their beers on offer. I settled on Pale Ale – fermented in the keg as are all their beers – and took in the scene. It was amusing to see some people – tourists I assume – entering, looking round and leaving with a look of dismay and concern on their faces. This was a proper pub.

However fabulous that proper pub on that wonderful evening might have been, it still can’t rank to probably the most fabulous beer related object ever… as witness by Lars:

However fabulous that proper pub on that wonderful evening might have been, it still can’t rank to probably the most fabulous beer related object ever… as witness by Lars:

Just saw this: the Oldenburg horn. A family relic of the Danish royal family, kept in the vault with the Danish crown jewels, so this really is the Danish royal drinking horn. And it has a legend attached to it… According to the legend, Otto, first of the house of Oldenburg, was out hunting back in 989 when he became thirsty and said “How I wish I had something to drink,” whereupon an elf maid appeared out of a hill with the horn…

You will have to read on for more of the elven lore. We of MacLeod are totally here for these sorts of things.

In Pellicle this week we have a good bit of writing from Rachel Hendry on the phenomenon known as Babycham, its cultural meaning, its logo as well as (a bit to my surprise) its content:

Thankfully an alternative name was already being used. Be it short for champion or champagne, Baby Champ—as the legend goes—was the term used by workers in the factory to distinguish the smaller individual bottles of Champagne de la Poire from their larger siblings. This term of endearment was overheard in an early marketing meeting held at the premises and adopted as a result. Baby Champ, then, became Babycham. Ralph Showering, you may recall, had been appointed head of sales and marketing, a position he did not take lightly. The Showerings family had purchased a small herd of Water Deer from Herbrand Arthur Russell, the 11th Duke of Bedford, for their growing property and it was here that Ralph took inspiration for Babycham’s logo.

I say a bit to my surprise as I spent my high school years over forty years ago in Truro, Nova Scotia. “Of course” you say, “the connections slaps one in the face!” But… in that place there was a factory next to the facory where I made carpets on the night shift for only one week one summer** which made such delights as Moody Blue sparking wine made in part from blueberries as well as Baby Duck made of God knows what. You may still be able to buy a magnum of it for $13.95.

Some classic Ron just after last week’s deadline, starting with a photo of a plate of breakfast and summing up like this:

I fiddle around on the internet for a while. While sipping whisky and stuffing my face. Eventually it says my flight is 45-minutes late. Though, by the time it leaves, it’s delayed by more than an hour. Not much to report about the flight. We take off, fly for a bit, land and then spend forever taxiing to the terminal. When I open my front door, there’s a cup of tea ready. Andrew tracked my flight this time.

Good. Cup of tea and a rest. That’s what Ron needed.

I’ve done a few modest sponsorship deals so it was interesting to read that the English Premier League is moving forward with a four year deal with Guinness as sponsor:

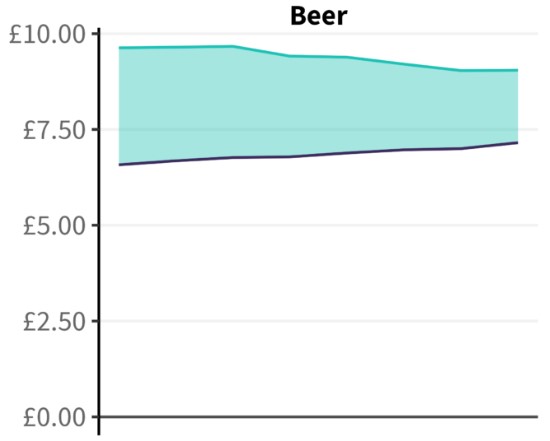

English football’s top flight is toasting a £40m sponsorship deal with Guinness after the Diageo-owned brand saw off competition from Heineken. Sky News has learnt that the Premier League has informed its 20 clubs, which include Everton, Manchester City and Sheffield United, that it is backing a £10m-a-year agreement beginning next season. The deal, which has not yet been formally signed, represents a big financial uplift on the Premier League’s existing partnership with Budweiser’s owner, AB InBev.

The match makes more sense than Bud… except it seems a bit, you know, cheap even though it is up from £7,950,000 a year for Bud.**** When you do a deal like this you should get some exclusive access to the fans in all those twenty fitba stands. That’s a lot of thirsty people. Unlike most naming rights sponsorship deals, the sponsor here actually should get a enhanced revenue stream in addition to loads of advertising and name placement. This boils down to £10 million divided by 360 games or £27,777 per league game not counting Cup or other games. Average game attenence so far is 38,486 meaning its 72p per attendee per game. Won’t this deal generate more value to Guinness than that?

Note: one of the reasons I look away whenever I see the word “neo-prohibitionists” is that the arguments from those who use it are so poorly made. Their cause may have a point… maybe… but, face facts, no government is shutting down the alcohol trade – the taxes are too sweet even if the behaviour causes so much harm. Which is the other reason: the dumb calls to liberty. It’s like that call for the liberty to starve under the highway overpass. The only argument that makes sense is that this is all about taking reasonable risks.

Much conversely, Boak and Bailey wrote a review of Dr. Christina Wade‘s The Devil’s in the Draught Lines which immediately saw me reaching for my iPhone so I could buy my own copy online:

Structurally The Devil’s in the Draught Lines resists the simplicity of chronology. Instead, each chapter covers a different angle and whizzes us back and forth through hundreds of years, from the mediaeval world to the 21st century. There’s also room for stories around race, culture, gender identity, with names and faces unfamiliar to us, like Lizzie and Lucy Stevens of Closet Brewing, and Apiwe Nxusani-Mawela of the Tolozaki Beer Company. In fact, there’s the equivalent of about 25 Pellicle articles hidden throughout the book – and we mean that as a compliment to both parties.

Inspired by the clever as I scanned the wide world for more beer reading, I saw that The Journal of The Institute of Brewing had released a few issues for 2024 on its relatively recent site and, while some can thrill to tales such as the “role of temperature in sporulation was investigated at 25, 27 and 30°C by measurement of the rate of sporulation over ten days,” this article drew my eye perhaps a bit more avidly towards the screen as it deals with that old chestnut, the diastatic variant:

Diastatic variants of Saccharomyces cerevisiae are unusual in producing an extracellular glucoamylase which enables the breakdown of starch to fermentable sugars. Diastatic S. cerevisiae has long been viewed negatively as a contaminant of especially beer packaged in cans or bottles. However, this view is being reconsidered due to the opportunities that diastatic strains present for niche fermented products and distillation applications…. This review highlights the utilisation of diastatic S. cerevisiae for its flavour potential, and processing applications in the brewing, distilling, and biofuel industries.

“Whachamacsayin’?” I hear you cry out? More in laypersonspeak over here at Escarpment Labs*** but I think we can all agree on need for increased oppportunities for niche fermentated products. Unless that means White Claw.

Treat of the week? Check out “Eating high” the 1966 video of the London Post Office Tower’s rotating restaurant included with this post at A London Inheritance.

Aaaaannnnnd… again we roll the credits… well, the credits, the stats the recommends and the footnotes and the many ways to find good reading about beer and similar stuff via any number of social media and other forms of comms connections.***** Want to keep up with the news before next Thursday? Check out Boak and Bailey every Saturday and Stan the very next Monday upon which he decides to show up at the office. Look at me – I forgot to link to Lew’s podcast. Fixed. Get your emailed issue of Episodes of my Pub Life by this year’s model citizen David Jesudason on the odd Fridays. And Phil Mellows is at the BritishBeerBreaks. Once a month, Will Hawkes issues his London Beer City newsletter and do sign up for Katie’s now revitalised and wonderful newsletter, The Gulp, too. Ben’s Beer and Badword is back with all the sweary Mary he can think of! And check out the Atlantic Canada Beer Blog‘s weekly roundup. There is new reading at The Glass which is going back to being a blog in this weeks best medium as message news. Any more? Yes! Check to see the highly recommended Beer Ladies Podcast. That’s quite good. And the BOAS podcast for the bro-ly. And the long standing Beervana podcast . Plus We Are Beer People. The Boys Are From Märzen podcast appears suspended as does BeerEdge, too. But not Ontario’s own A Quick Beer. There is more from DaftAboutCraft‘s podcast, too. All About Beer has introduced a few podcasts… but some may be losing steam. And there’s also The Perfect Pour. Plus follow the venerable Full Pint podcast. And the Craft Beer Channel on Youtube. The Moon Under Water… is gone which is not surprising as the ask was $10 a month. Pete Brown’s costs a fifth of that but is writing for 47 readers over there. There was also the Beer O’clock Show but that was gone after a ten year run but returned renewed and here is the link! Errr… nope, it is gone again.

*The actual scene that very evening as personally witnessed by the Tand.

**See, the shift was from midnight until noon for some unknown reason. Plus I was coated outside and in at the end of every shift with polyester from the spinning machines I was to operate. Good wage but goodbye.

***See, for example: “Saccharomyces cerevisiae var. diastaticus is beer yeast that can break down longer-chained carbohydrates (dextrins and starches) that regular yeast can’t. It doesn’t actually consume them directly, but it secretes an enzyme (glucoamylase) that breaks down dextrins outside the cell into smaller sugars that the yeast can then metabolize.“

****All stats via Lord Goog. Math by me. Govern yourselves accordingly.

*****This week’s update on my own emotional rankings? Facebook still in first (given especially as it is focused on my 300 closest friends and family) then we have BlueSky (up one to 128) rising up to maybe… probably… likely pass Mastodon (down one again to 915) in value… then the seemingly doomed trashy Twex (up five to 4,472) hovering somewhere above or around my largely ignored Instagram (161), with sorta unexpectly crap Threads (43) and not at all unexpectedly bad Substack Notes (1) really dragging up the rear – and that deservedly dormant Patreon presence of mine just sitting there. Fear not!