Did you know that there are five Thursdays this February? FIVE!! I thought I was done for the month today – but I am not. It’s leapday Thursday next week. This will be only the third one in my lifetime, now in my 61st year having lived through this experience in 1968 and 1996. The fifth since the 1800s. The responsibilities for next week’s update have suddenly loomed ominously. Am I up to this rich and rare Thursdayness? The very first leap day Thursday since beer blogging began? Better put an effort in. A big effort. So… I can slack off this week and no one will notice. Excellent.

First up,  Boak and Bailey are doing some clever things with their multi-media channels. For one thing, they are posting footnotes to their weekly beery news roundups on Patreon. As you can always see below, I like footnotes but rather than merely wallowing in snark like I do BB2 actually add a bit of context and discussion.* And, as you can see to the right, they play with the graphical display of information like with this table explaining their thought on what has been gained and lost over the last ten years of good beer in the UK. They published that in their monthly newsletter after gathering some thoughts from readers over at Bluesky. Which I received by email. Where do they find the time?

Boak and Bailey are doing some clever things with their multi-media channels. For one thing, they are posting footnotes to their weekly beery news roundups on Patreon. As you can always see below, I like footnotes but rather than merely wallowing in snark like I do BB2 actually add a bit of context and discussion.* And, as you can see to the right, they play with the graphical display of information like with this table explaining their thought on what has been gained and lost over the last ten years of good beer in the UK. They published that in their monthly newsletter after gathering some thoughts from readers over at Bluesky. Which I received by email. Where do they find the time?

And I wrote something last week that caught even me by surprise: “could it be that beer might actually… be going out of style?” For years that was the quip – it’s not like its gonna go out of style. Did I mean it? I mean sure we all know that democracy and simple human decency are well on their way out… but beer?!?! It seems something it up… or, rather, quite a bit down. Stan posted another graph building on the graphs discussed seven days ago. I can’t just put the same graph at the top of my roundup this week (because that would break the weekly updaters Code of Conduct that B+B control with a ruthless efficency) but his point is worth repeating:

The pink on the right represents barrels of beer that would have been sold had sales simply gone flat in 2020, rather than declining, not completely recovering, then declining again. Obviously, that matters a lot to hop growers. When barrels aren’t brewed then hops aren’t used. In this case, about 20 million pounds of them. Two thoughts. First, indeed, little difference between production in 2015 and 2023. Second, if you draw an arrow from the top of the bar at 2015 to 2019 it looks much different than an arrow drawn from the top of 2019 to 2023. Production might be the same, but something different is going on.

One thing I do not believe is causing all this is the lack of detailed description of the offerings at taproom. Jim Vorel would beg to differ and does so at length:

Case in point: Not long ago, my wife was ordering at a large, well-funded and popular local brewery taproom. Looking at the electronic menu above the bar, she landed on a new beer labeled simply as “coffee stout.” She loves stout, and lightly adjuncted classic stouts such as coffee stouts, so she ordered one. The reality? The beer was actually a stout with “vanilla, caramel flavoring and cardamom” in addition to the coffee, which was the only thing mentioned by the sole source of information available to the consumer. Is that a valid concept for a “Turkish coffee stout,” or whatever? Absolutely it is, but the customer needs to know they’re ordering a stout with that kind of theming when they place the order. You can’t just surprise someone with “caramel, vanilla, cardamom” when they think they’re ordering a relatively dry beer. What if that person doesn’t really care for pastry stout concepts? Are they supposed to grill the bartender whenever they see “coffee stout,” to ask if there are any other adjuncts involved? Just how many questions are we expecting these busy taproom employees to answer?

Theming? I had no idea. Me? I just taste the stuff and make my own mind up. Now, let’s be clear. That graph showing US craft beer (including formerly recognized craft brewers kicked out of the BA) have slumped back to 2015 production levels** does not mean all beer is going out of favour, as Jessica Mason explained:

Molson Coors delivered six years of profit growth, six years of growth in just one year. That focus is a new baseline. We are ready for this moment”. To illustrate the size of the achievement, Hattersley explained: “In 2023, our top five brands around the world drove over two million more hectolitres than they did the prior year. This is like adding the entirety of Blue Moon’s global volume to our portfolio.” Looking at America, Molson Coors has seen a boost in both its distribution as well as its presence in supermarkets with more retailers listing its beers. In fact, this momentum and knock-on revenue spike is what has boosted the business to such great heights and reinforced distributor confidence in listing Molson Coors’ beers.

And Kirin is experiencing a bounce as well according to Eloise Feilden:

Kirin Holdings posted revenue of ¥2.1bn (£11.1m) in the year to 31 December 2023, representing a 7.3% rise year-on-year. Profit was up 4.6% on 2022, and operating profit rose 29.5% to ¥150.3bn (£79.4m). Revenue from the Kirin Brewery division was up 3.2% on 2022 to ¥685m. Kirin Brewery’s total beer sales increased 5.9% to 1.4bn litres. CEO Yoshinori Isozaki told analysts that price changes in October helped to boost beer sales “more than expected”, after the company dropped the price of beer brands including Kirin Ichiban. Kirin raised prices for its no-malt Honkirin and Kirin Nodogoshi Nama beers.

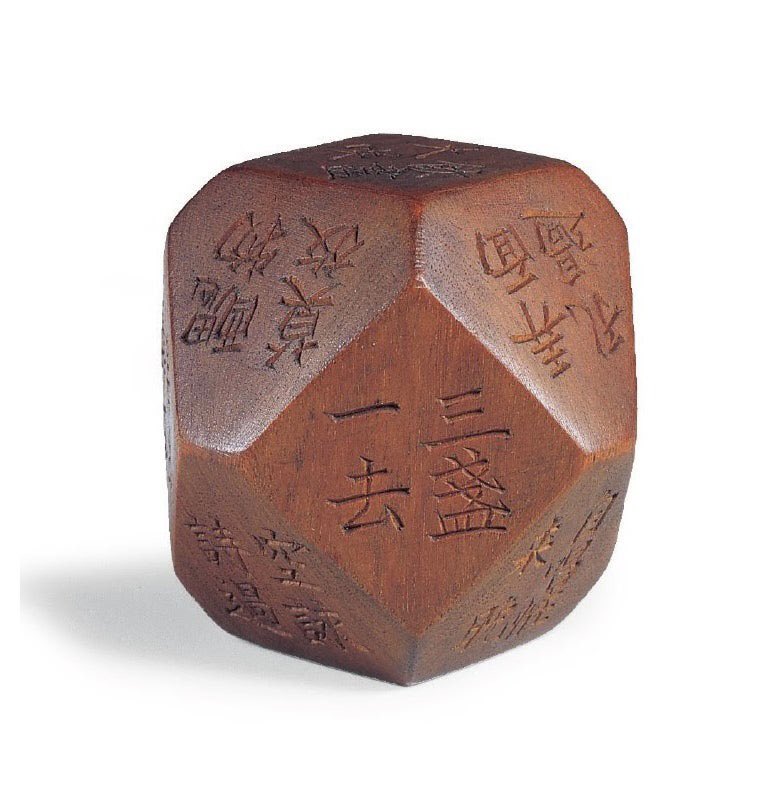

Interesting. So are people really just getting fed up with the craft beer nonsense? Remarkably, it’s been a decade since the cult classic The Unbearable Nonsense of Craft Beer by Max and Myself was published – and this remarkably visionary review (given the interveining rise and fall of craft) by Alistair popped up in my Facebook feed this week:

I’ve been slowly reading my way through The Unbearable Nonsense of Craft Beer by Alan and Max, and finding myself agreeing with most things, especially when it comes to tasting vs drinking. I’ve been saying it for a while now, beer is for drinking, not standing around pontificating about the supposed terroir of the hops, the provenance of your peat-smoked 80/- (as in it has none), or worst of all thinking that Pilsners are just American Light Lager without the rice or corn (have heard that more than once). I guess that’s one reason why I love breweries that make classic styles, and make them well, rather than brewing every gimmick going – you know they can make good beer, worth drinking, instead of random shit to taste a thimbleful of and never want to touch again.

Point. And Alistair (as well as someone in the comments) made the analysis that is often made in tighter times – is home brew really cheaper? Why yes, yes it is:

Thankfully, I don’t have to pay myself to make beer, neither do I pay myself to serve the beer, and so the real cost for a half litre of my own beer at home is about $2. One thing though that is really clear to me from this little exercise is that ingredients are not the bulk of the cost of making the beer, it is a the people, equipment, and place to do so. Obviously I am also not able to take advantage of the economies of scale that a commercial brewer (sorry idealogues, if your favourite beer is made by a company that does so for a living it IS a commercial brewery), especially when it comes to non-linear increases such as the ingredients, and don’t forget to factor in that a single decoction brewday in my garage takes about as long as a single decoction brewday at a professional brewery with the appropriate kit.

But… and I am a long lapsed home brewer… you don’t need the equipment and you don’t need the decoction. A nice pale ale or porter from scratch? Do it. Conversely, care of the BBC, here’s another reason I’ll steer clear of NA beer for the foreseeable future – unlisted ingredients:

UK-based brewer, Impossibrew, which specialises in non-alcoholic beers, uses a different means of arrested fermentation. “We brew it in such a way that we can cryogenically stop the fermentation process,” says founder, Mark Wong… Impossibrew also adds its “proprietary social blend”, a mix of nootropic herbs designed to imitate the feeling of relaxation induced by traditional beer. It is a precise blend developed in collaboration with Professor Paul Chazot at Durham University’s Biophysical Sciences Institute. Nootropics are natural compounds – billed as “smart drugs” – which improve cognitive functions.

Sweet. Playing with the psychological therapies. Here is a 2023 paper on nootropic herbs. Including a discussion of the allergies and side effects*** that one might encounter… if you knew what you had consumed.

Pellicle‘s offering this week is a portrait of Bristol, England’s Wiper and True taproom by Anthony Gladman.**** Spoiler – they have a dealcoholiser:

The second tool is a reverse osmosis dealcoholiser, which the brewery uses to remove the alcohol from beers like Tomorrow, and the low alcohol version of Kaleidoscope, which launched in January 2024. “That’s going to be a big push for us for the next… well, for a long time actually,” Michael says. “That’s what the whole business is galvanising around at the moment.” Installing a dealcoholiser is not something a brewery does lightly: the equipment is a huge expense, but so too is the floor space it requires, as well as the staff training, and the effort in recipe research and development to make owning one worthwhile.

Note: The Beer Ladies Podcast interviewed Lars this week. Have a listen.

Merryn has shifted to Bluesky and is still tracking the research on ancient grain residues. We learn that “interest in bread like, porridge like, lumps of charred cereal residues certainly has increased over the past decade.And quite a lot have been found” like in Ancient bread recipes: Archaeometric data on charred findings from the February 2024 issue of the Journal of Cultural Heritage:

This study examines charred bread-like samples found in several archaeological sites across northern Italy and dating from the Early Bronze Age to the Early Middle Ages, some of which are included amongst the UNESCO World Heritage Sites. The aim is to investigate differences and homogeneities in bread production processes in different eras and cultures. Bread was a staple food in many ancient societies, but has rarely been found amongst the materials that survive in archaeological sites. When it is found, it is usually because the bread was charred by accidental combustion (falling into the oven during baking) or deliberate combustion (for ritual purposes). The literature on the issue is not abundant, but has been growing over the past decade

It’s beer, isn’t it. Err… wasn’t it. Speaking of was, some bad news for beer drinkers in Nigeria:

The Chief Executive Officer of Nigerian Breweries Plc, Hans Essaadi, has said that the economic situation in Nigeria has deteriorated to the extent citizens can no longer afford to buy beer. Essaadi said this on Monday at the company’s investor call following the release of its 2023 results. “It has been unprecedented year for our business in Nigeria. We saw a significant decline in the mainstream lager market as a result of Nigerian consumers no longer able to afford a Goldberg after a hard day’s work,” Bloomberg quoted Essaadi as saying.

Note: no GBH Sightlines for five weeks. Done?

Like clockwork, Stan has posted his February edition of Hop Queries – which is not a quote from Shakespeare, by the way. He built upon that glut of hops mentioned above, twisting the knife just a bit:

My story about why farmers in the Northwest are ready to remove 10,000 acres (about 18 percent of what was harvested last year) from production in 2024 has posted at Brewing Industry Guide (subscription required). Short term, this means there are plenty of hops out there, often at bargain prices.

Long term, think about how many times you have seen the term “soft landing” used when discussing the American economy. How does that usually work out? The market for hops has always been cyclical and landings have not often been soft. It will be a year or more before it is clear if this year is different.

Finally and speaking of honesty, consider this exchange in the comments at Beervana and ponder whether

Reader: Jeff, big fan of your blog and content. That being said, I would hope that we don’t start bashing beers here. The battle for beer should not be within the community but outside of it against wine and spirits. If we bash our own, regardless of how “eye-rolling” the content is we will lose the long game.”

Jeff: “Mason, it’s not my job to promote the brewing industry here. I try to write honestly and entertainingly about beer, and that means I criticize things from time to time. My “clients” are my readers, not breweries. Beyond that, I would argue that anyone who did want to promote the brewing industry would not whitewash negative stories, bad beers, or disappointing news. Concealing faults doesn’t help in the long run.”

Very well said, Jeff. One wonders how much this sort of call to disengagement from reality based reality that craft beer too often promotes has contributred to the slide that we discussed up top. That we see all around us. Maybe that’s what “theming” is. By the way, has anyone brewed a samey Doubly Hazy NEIPA and called it “Self Inflicted Wound”? As things change and interest in craft declines, it’s still good to watch how it falls if only to identify what stands the best chance of coming through the downturn.

OK. Mailed that one in. Didn’t even have to mention BrewDog. Or baseball now that I think of it. Fine… just roll the credits… well, the credits, the stats the recommends and the footnotes. There is a lot going on down here and, remember, ye who read this far down, look to see if I have edited these closing credits and endnotes (as I always do), you can check out the many ways to find good reading about beer and similar stuff via any number of social media and other forms of comms connections. This week’s update on my emotional rankings? Facebook still in first (given especially as it is focused on my 300 closest friends and family) then we have BlueSky (up again to 123) rising up to maybe… probably… likely pass Mastodon (913) in value… then the seemingly doomed trashy Twex (4,450) hovering somewhere above or around my largely ignored Instagram (up to 165), with sorta unexpectly crap Threads (43) and not at all unexpectedly bad Substack Notes (1) really dragging up the rear – and that deservedly dormant Patreon presence of mine just sitting there. I now have admitted my dispair for Mastodon in terms of beer chat, relocated the links and finally accept that BlueSky is the leader in “the race to replace” Twex even while way behind.

Fear not! While some apps perform better than other we can always check the blogs, newsletters and even podcasts to stay on top of things including the proud and public and certainly more weekly recommendations in the New Year from Boak and Bailey every Saturday and Stan really doing what needs to be done Mondays. Look at me – I forgot to link to Lew’s podcast. Fixed. Get your emailed issue of Episodes of my Pub Life by this year’s model citizen David Jesudason on the odd Fridays. And Phil Mellows is at the BritishBeerBreaks. Once a month, Will Hawkes issues his London Beer City newsletter and do sign up for Katie’s now revitalised and wonderful newsletter, The Gulp, too. Ben’s Beer and Badword is back with all the sweary Mary he can think of! And check out the Atlantic Canada Beer Blog‘s weekly roundup. There is new reading at The Glass which is going back to being a blog in this weeks best medium as message news. Any more? Yes! Check to see the highly recommended Beer Ladies Podcast. That’s quite good. And the long standing Beervana podcast . There is the Boys Are From Märzen podcast too and Ontario’s own A Quick Beer. There is more from DaftAboutCraft‘s podcast, too. All About Beer has introduced a podcast… but also seems to be losing steam. And there’s also The Perfect Pour. Plus follow the venerable Full Pint podcast. And the Craft Beer Channel on Youtube and remember BeerEdge, too, and The Moon Under Water… if you have $10 a month for this sort of thing… I don’t. Pete Brown’s costs a fifth of that. There was also the Beer O’clock Show but that was gone after a ten year run but returned renewed and here is the link! Errr… nope, it is gone again according to Matty C.

*I mean consider this: “We have taken note of, and pre-ordered, Dr Christina Wade’s upcoming book The Devil’s in the Draught Lines about the history of women in British brewing. We nearly gave it a shout out (free advertisement) in this week’s round-up but decided to save that for next week. But, blimey, eh? CAMRA’s publishing strategy is interesting these days. You might call it public service publishing, doing what’s right for the good of the beer culture rather than what’s commercial (101 beers to drink before you die… again!). Except Desi Pubs seems to have been a substantial success.” That’s a proper bunch thoughts right there.

**IE: not actually “flat” at all.

***Note: “Plant nootropics are generally very well tolerated, but potential users should consider their overall health condition and consult a doctor about possible contraindications and drug interactions before trying a particular plant formulation.“

****This piece serves as an interesting counterpoint to Boak and Bailey’s thoughts from last July whose words from them bear repeating: “It used to be a ‘beer garden’ – a bare yard full of tables. It felt like having a pint in the car park of ASDA. But now it is a Beer Garden, or at least heading well in that direction. Around the perimeter are tall plants providing a green shield. In the garden between tables, there are loaded beds and planters. Grasses, shrubs and young trees soften edges, dampen sound and create depth. This is now a pleasant place to be, like a park or botanical exhibition.“