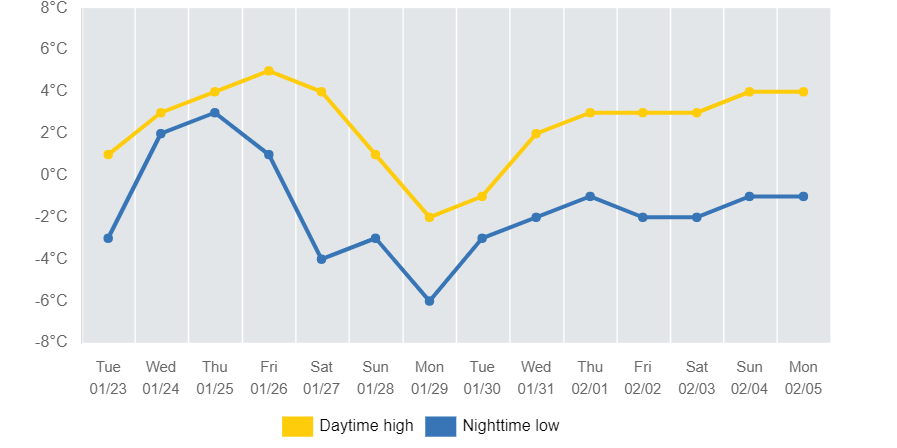

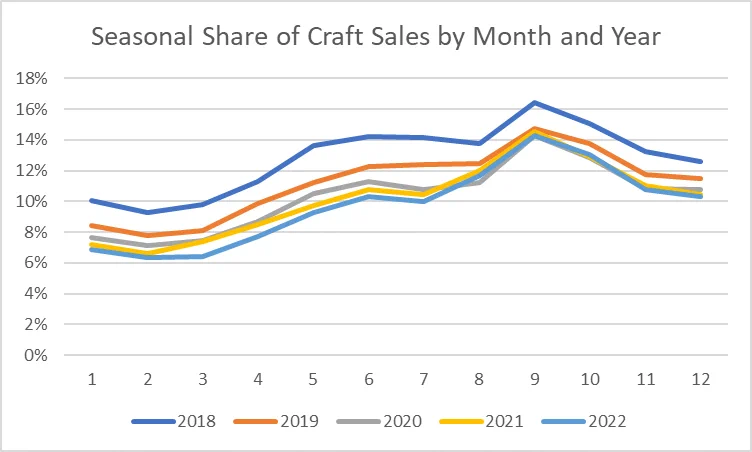

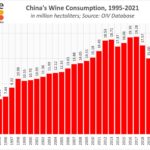

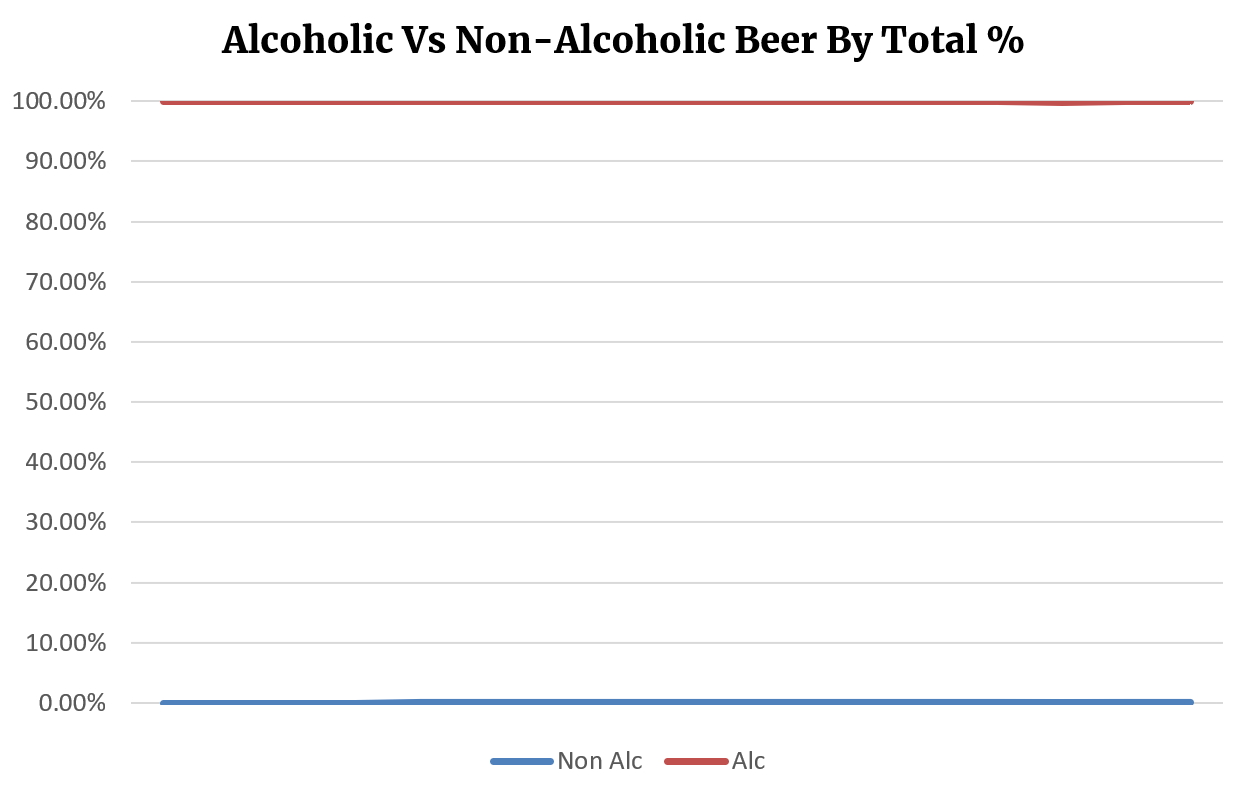

Let’s get right into it. Jeff posted the graph right above us right there this week which deliciously not only sums up the place of non-alcoholic beer in the US market but also, as any good specific graphical representation of data, also invites us to consider any number of the crises in beer or in all of life itself. Is it neo-proto-Dada? Not sure but it really poses the question “what is big?” BA Bart, who actually started the discussion with this graph, responded with a fact as well as perhaps as something that was less than a fact when he countered with another graph:

Let’s get right into it. Jeff posted the graph right above us right there this week which deliciously not only sums up the place of non-alcoholic beer in the US market but also, as any good specific graphical representation of data, also invites us to consider any number of the crises in beer or in all of life itself. Is it neo-proto-Dada? Not sure but it really poses the question “what is big?” BA Bart, who actually started the discussion with this graph, responded with a fact as well as perhaps as something that was less than a fact when he countered with another graph:

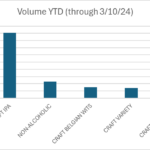

All depends on your point of view. From one view 0.8% share isn’t that much. But 1 share of the US beer mkt is >$1 billion in consumer spending & NA is now bigger than any craft style except IPA (category vs style within category is admittedly a bit apples to oranges).

I have to admit that I am personally far more interested in the graphical display of information than I am in NA beers – but the question of what is “big” remains. Very much relatedly, Andreas Krennmair wrote about a sort of “wow – this is big!“: a NA beer from Germany’s venerable brewers Augustiner:

Everything I’ve read about the Augustiner Alkoholfrei Hell sounds to me as if Augustiner may have pulled off the same as Guinness, to release a convincing alcohol-free Helles that may be pleasing even to consumers and Augustiner fans that otherwise would not choose an alcohol-free beer. That’s a big deal, and could change the landscape and expected quality of alcohol-free beer in Bavaria and the rest of Germany.

See, as Andreas says, Augustiner was the last of the big Munich brands without an NA beer. And NA beers, in Germany, are big. In other big news, lots of good coverage by James Beeson in The Grocer this week on the purchase of “parts of”* craft beer distributor Eebria by Beer52 and the effect on suppliers to Eebria now holding invoices unlikely to be paid. He’s added a few extra considerations by Twex, too, including this on Wednesday:

Have this AM seen a copy of the SIP16 doc pertaining to the sale of @EeBriaTrade. Was initially marketed as for sale as early as March 2023 (i.e. it had been in financial distress for some time). A buyer pulled out in Dec ’23. Beer52 paid a total of just £30k to acquire. Doc makes reference to the fact the sale process(es) needed to be carried out discretely so as to reduce risk of “supply partners withdrawing their products”, something that “would impact upon the company’s ability to trade and significantly affect the value of the business.”

It is important to note that buying or not buying debt as part of administration is a common choice. If you are not a dealer in debt it is risky to take it on. It’s also important to note that pre-pack administration set ups (if not managed correctly) are not immune from supplier backlash or even allegations of fraud related to the “pre-packing” process. As always, suppliers with concerns related to questions on possession as opposed to ownership of stock in hand should seek qualified independent legal advice. By this I mean, if you did not buy the debt did you really buy the stock associated with that debt? By which I mean… where is the beer and is the possession lawful?** These things are regulated in Canada. There is also a UK police hotline, ActionFraud, which specifically deals with firms “fraudulently trading immediately before being declared insolvent, or phoenix companies.” I make no comment on current situation other than to say suppliers left out of pocket in the UK seem to have sources of professional legal and policing assistance.

Entirely unregulated and certainly well above it all, I so admit that know I have posted about this orchard project a few times. But, as a very minor investor, I have a rather outsized proprietary interest in the experimental forest of rare cider and perry trees of Barry Masterson, the motives behind of which he shared in Cider Review:

What drives a person to do something like that? For me, it began with Flakey Bark. A kind of poster child for rare pears, though believe it or not, there are rarer varieties than that one that was rediscovered by Charles Martell while driving a horse and cart through the Herefordshire countryside. Six known mature trees. Six. Though there are a couple of young trees at the National Perry Pear Centre at Hartpury, Gloucestershire. And now there are two more, planted in a field in Schefflenz, Germany. If it wasn’t for the Ross-on-Wye Cider and Perry Company, we’d likely never have heard of it.

Wow. Really wow. Me? I transplanted my lavender plants this week into ten peat pots as unattractively illustrated to the right. I started each and every one of them from seeds. So… samesies!

Wow. Really wow. Me? I transplanted my lavender plants this week into ten peat pots as unattractively illustrated to the right. I started each and every one of them from seeds. So… samesies!

Wetherspoons. Love them or hate them, they appear to be either fighting against the tide of bad pub news coming out of the UK or… maybe they are part of the problem. The appropriately named Harry Wallop spent 24 hours in one to investigate for The Times:

It is 12.38am on a Friday night and I have spent nearly 15 hours in the Briar Rose, a Wetherspoons in the centre of Birmingham. Hannah, a law student, is about to head off to Snobs nightclub, but only after she has grabbed my arm to explain to me the appeal of the pub chain. Though she is articulate, she has also had “quite a few” Au Vodkas (£5.29 for a double, including her orange juice mixer). There is something about her enthusiasm that riles her friend Jacob, a politics student. “We don’t want to be here. We’re only here because it’s cheap,” he argues. “That is such bullshit,” says Hannah, rising to her feet.

Also down the ‘Spoons, The Beer Nut has been doing is own investigations of the wares on offer. No word of the volitilitiey of the “doubles Au Vodkas a la Hannah” but plenty of other observations:

It’s funny how branches of pub chain JD Wetherspoon develop personalities for themselves. Of the three in central Dublin, The Silver Penny, in the north inner city, isn’t the biggest, but it always feels like the busiest, the loudest, the endless party on the verge of kicking off. None of that has anything to do with cask beer, and yet it’s the one that does the most to put cask beers on. At festival time, it seems to give everything its turn, where the other two branches don’t seem so committed. That’s a long introduction to say that virtually everything I drank at the Spring 2024 JD Wetherspoon Beer Festival, I drank at the ‘Penny.

Speaking of festivals, the BBC reported on one which went rather wrong:

The first International Brewing and Cider (IBC) Festival was held in Manchester over the weekend. But the not-for-profit event was hit with complaints about rude staff, cold conditions in the Mayfield Depot venue, and a poor atmosphere… Freddy Hardy, co-founder of independent Manchester brewery Courier Brewing Co. said a low turn out in such a large venue meant “the vibe… just wasn’t there”. The 35-year-old added that he had agreed to stay until the end on Friday, but estimated he had only sold beer to around 20 people – 10 of whom he believed to be other people from the industry… Manchester-based beer writer Matthew Curtis told the BBC he estimated crowds to be no bigger than 50 to 100 at any time. He described the atmosphere as “very muted”.

Note that cameo appearance! Sometimes co-conspirator extraordinaire Katie added this:

Can confirm rusty rainwater dripped from the roof into my drink

That’s almost a haiku, right there. Or a bit of a folk song. Staying with the only two real controversies in British pub trade but moving on to the other… everyone’s favourire retired Fullers brewer John Keeling writing in Brewers Journal unpacked the sparkler debate for us who are not really in the know:

I am going to weigh in on this debate with my customary diplomacy. Northern beers use them to produce a massive head which certainly makes the beer look good and appetising but southern beers have a looser fluffy head. If you pour beer from a cask into a glass, you will get a very small head indeed and this was the way beer was dispensed before the invention of the beer engine. This produced a bigger head, but it needed the invention of the sparkler to produce the tight creamy heads much loved by Northern drinkers. However, it might look good, but does it taste better?

You know what looks good? This scene from Ireland.  What a lovely image from 53 years ago. Shared by Dublin By Pub on Twex, no word of the ultimate source but with the caption:

What a lovely image from 53 years ago. Shared by Dublin By Pub on Twex, no word of the ultimate source but with the caption:

Livestock traders drinking outside a pub on Inis Meáin island, 1971.

Speaking of loverly, Retired Martin has taken us along to see the unexpected splendor of the newly reopened Rochdate Town Hall with a fabuous photo essay that you really need to go check out:

Mrs RM said “Wow”.

Speaking of a bit of another wow but just in time for Easter…

A congregation of Catholic nuns has reopened a bar in an ancient sanctuary in northern Spain, pulling pints of beer in the hopes of spreading the word of God to thirsty guests visiting the 11th-century Romanesque site. “I think plenty of people would think it’s unusual, because they’ve never seen it. But you know, it’s not a sin to drink a beer,” said Miami-born Sister Guadalupe, adding that the bar constituted an “open door for us to evangelise”.

Certainly with the same intention, Ron was back in Brazil for the hotel breakfasts and fit in another one before heading to at Marstons and drinking a lot of Bass [Ed.: passage edited for clarity]:

We start with some Bass that’s been open for a few days. It’s dry and finishes satisfyingly bitter. And no trace of sulphur. Quite like the pint in the Smithfield. Moving on to a freshly-tapped Bass, the contrast is striking… It’s time to go and drink some beer. In town… Guess what we’re drinking? You’ll never get it. Bass!… We need to be moving on. Not far. To another pub… Why not have a Bass?… “Fancy a pint in the White Horse?” Mike asks. It’s the pub opposite our hotel. “Why not?”… They’ve got Bass.

Now… there’s a lot of reading out there… so some quick takes like “Is craft beer cringe now?” asked Courtney Iseman. As she writes, “now” is a long time:

Even then, though, “craft beer drinker” was an easy shorthand for mocking hipsters. See: this New Yorker cover from 2014.

“What does ‘fine wine’ really mean?” asked Simon J Wolfe, sounding familiar:

In other words, this has nothing to do with wine – as in the liquid in the bottle.

Wholesale pricing notes from The Beer Nut:

Your regular reminder here that pubs buy beer from independent breweries for less than the big brewers charge, but sell it dearer, just because.

Boak and Bailey on “Real Ale as Folk Horror“:

The main point is that many of the stories concern secretive cults which are unwelcoming to outsiders and cling to arcane practices and rituals. Which brings us to CAMRA.

And… somewhat similarly but not… can we expect someone or something to brew a “Six Finger Stout“?

…researchers say they have harnessed the power of artificial intelligence to make brews even better.

Heavy lifting the word “say” right there. And “West Virginia passes bill allowing home distillation” says NPR with a netly hidden note of doom in the word “celebrate”:

West Virginia’s legislature has approved a bill that would allow individuals to distill up to five gallons of moonshine as a way to celebrate Appalachian history and heritage.

I like how “history” (the actual) and “heritage” (the bits of history that conveniently support whatever the hell you want) are used. Good to see the what was apparently the original level of 50 gallons a year per household was reduced.

Hops news? We got the hop news. Indoor hops farms in Spain? Check. Genetic intervention to preserve Kentish strains? Check. And Stan in his monthly Hop Queries clarifies his thoughts on the term “landrace” comfortably in line with my thoughts. First his thoughts:

Hop geneticists refer to the varieties that farmers chose to propagate over the course of centuries as landrace hops. Val Peacock, long-time manager of hop technology at Anheuser-Busch and now a consultant, explained the decision was pretty basic. “We like the hop that grows on this side of the road. We’re not so happy with the hop that grows on that side of the road”… I prefer the word “landrace” to “noble” because it is more encompassing. The more diverse the population of hops that breeders have to draw from, the more diverse the selection of new varieties brewers will be able to choose from, whether they are seeking old world or new world flavors.

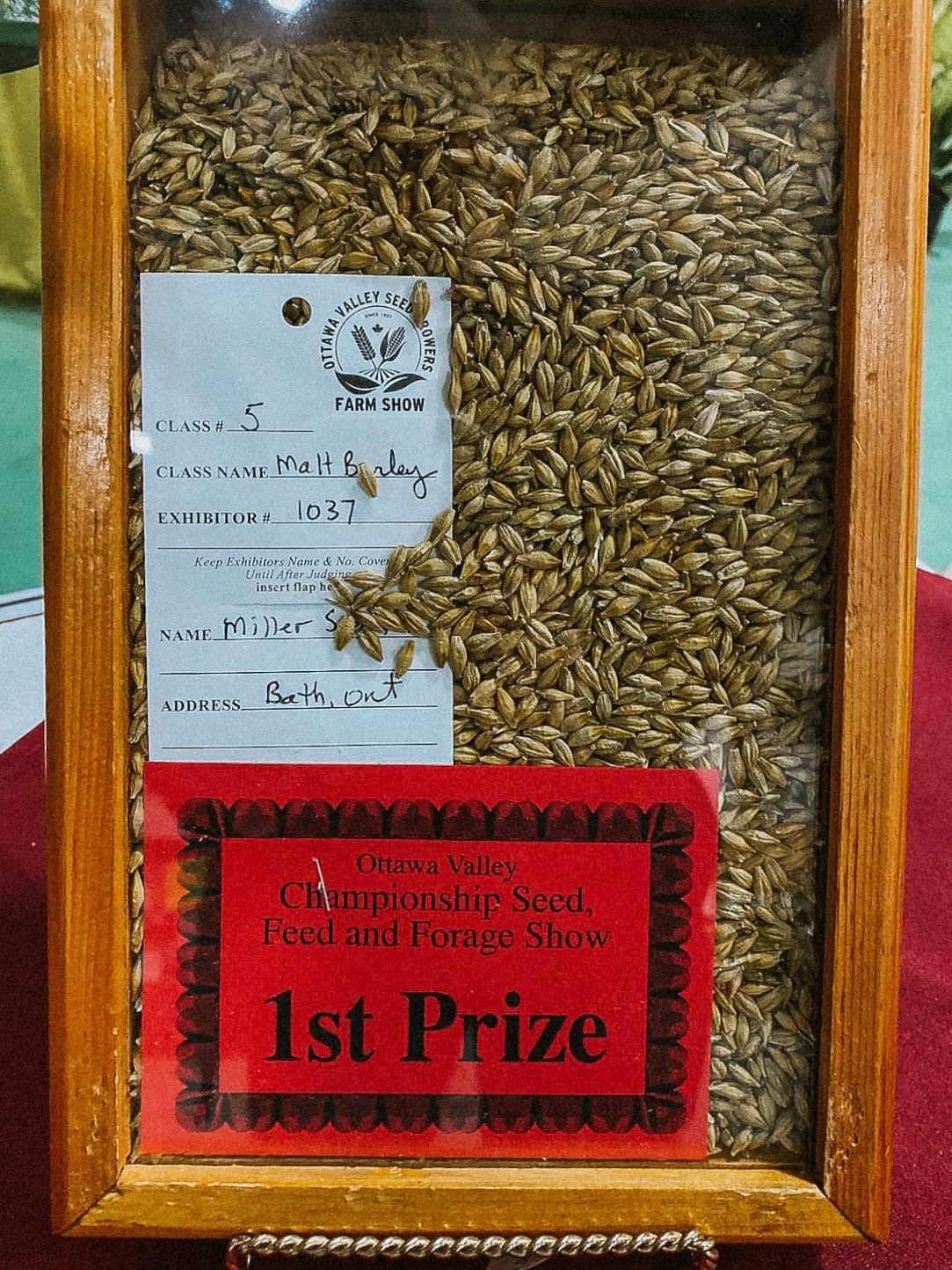

Me? I do not care for when people use “landrace” to mean wild. Centuries before the 1800s when the concept of nobel hops shows up, farming husbandry was selecting preferred stock. You see it in hops history and malting barley history. People in the past used the resources around them in clever ways. They were not waiting for our own short stage of their future hoping we would be cleverer. Speaking of cleverer, Hollie Stephens in Pellicle describes some hybridizing hopsters:

Indie Hops formed a partnership focused on hop research and breeding with Oregon State University (OSU), breathing new life into the university’s well-established hop research, which has been evolving since scientists planted hops on the campus in 1893. The business provides 100 per cent of the program’s funding and sets direction for what they want to achieve. But it’s truly a team effort to bring a new hop into the world.

Finally, a wonderful photo from brewer Paul Spencer of his team as they start the process of making a new beer with a special ingredient:

And again we roll the credits… well, the credits, the stats the recommends and the footnotes and the many ways to find good reading about beer and similar stuff via any number of social media and other forms of comms connections. This week’s update on my own emotional rankings? Facebook still in first (given especially as it is focused on my 300 closest friends and family) then we have BlueSky (126) rising up to maybe… probably… likely pass Mastodon (up one at 914) in value… then the seemingly doomed trashy Twex (4,465) hovering somewhere above or around my largely ignored Instagram (163), with sorta unexpectly crap Threads (43) and not at all unexpectedly bad Substack Notes (1) really dragging up the rear – and that deservedly dormant Patreon presence of mine just sitting there. Fear not!

Want to keep up with the news before next Thursday? Check out Boak and Bailey every Saturday and Stan the next Monday. Look at me – I forgot to link to Lew’s podcast. Fixed. Get your emailed issue of Episodes of my Pub Life by this year’s model citizen David Jesudason on the odd Fridays. And Phil Mellows is at the BritishBeerBreaks. Once a month, Will Hawkes issues his London Beer City newsletter and do sign up for Katie’s now revitalised and wonderful newsletter, The Gulp, too. Ben’s Beer and Badword is back with all the sweary Mary he can think of! And check out the Atlantic Canada Beer Blog‘s weekly roundup. There is new reading at The Glass which is going back to being a blog in this weeks best medium as message news. Any more? Yes! Check to see the highly recommended Beer Ladies Podcast. That’s quite good. And the long standing Beervana podcast . Plus We Are Beer People. There is the Boys Are From Märzen podcast too and Ontario’s own A Quick Beer. There is more from DaftAboutCraft‘s podcast, too. All About Beer has introduced a few podcasts… but some may be losing steam. And there’s also The Perfect Pour. Plus follow the venerable Full Pint podcast. And the Craft Beer Channel on Youtube and remember BeerEdge, too, and The Moon Under Water… if you have $10 a month for this sort of thing… I don’t. Pete Brown’s costs a fifth of that. There was also the Beer O’clock Show but that was gone after a ten year run but returned renewed and here is the link! Errr… nope, it is gone again.

*As succinctly quoted by Boak and Bailey last Saturday.

**See the fabulously named civil cause of action “replevin” (as discussed in the reasonably recent case Gignac v. Move Me Again Transportation Inc, 2021 ONSC 3374) which is a request for the return of someone’s personal property where it is alleged that the property is unlawfully detained by another someone.