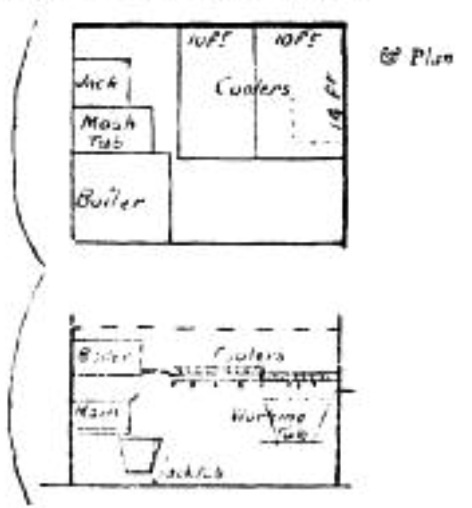

OK, sure this is actually a brewer in Geneva, New York and not one on Albany… but it is an actual brewhouse from 210 years ago even if it was 190 miles or so to the west. And it is one described in quite a bit of detail in the 1803-04 travel diary of Lord Selkirk as he travelled through the lower Great Lakes preparing his settlement at Baldoon, Upper Canada. Having come from Boston, on November 9, 1803 Selkirk was moving west through the Finger Lakes heading towards the Niagara frontier and at Geneva met with a Mr Grieve who owned a distillery and a brewery. He took careful notes and even drew sketches like this diagram of the brew house. There is a fair amount of material here so let’s take it a bit at a time.

OK, sure this is actually a brewer in Geneva, New York and not one on Albany… but it is an actual brewhouse from 210 years ago even if it was 190 miles or so to the west. And it is one described in quite a bit of detail in the 1803-04 travel diary of Lord Selkirk as he travelled through the lower Great Lakes preparing his settlement at Baldoon, Upper Canada. Having come from Boston, on November 9, 1803 Selkirk was moving west through the Finger Lakes heading towards the Niagara frontier and at Geneva met with a Mr Grieve who owned a distillery and a brewery. He took careful notes and even drew sketches like this diagram of the brew house. There is a fair amount of material here so let’s take it a bit at a time.

=> I am I think finally full redeemed! Well… redeemed ish. See, it is a wheat ale operation:

…half barley half wheat he uses about 500 Bushels of barley vis all that he can find to buy & pays the price of wheat – being very little cultivated… Wheat alone makes thick stuff & the liquor will not run of from the grain – sometimes by the assistance of a mixture of Chopt straw it can be done, but the wheat at any rate does not improve the quality of the beer…

See, I have been writing about indigenous strong wheat ale brewing in New York for over three years now but have never seen it described. Now I have an eyewitness account.

=> And it is strong ale. Grieve speaks of making stronger ale for storage through a summer but is brewing for present us an ale with 3.5 to 4 bushels of malt per barrel. Now check my math but when I tried to work out the strength of an 1835 Albany ale a few years ago I came up with a figure north of 8%. What would the strength of his proposed 5 bushel keeping beer be?

=> The brewing process is both described and illustrated. Click on the picture above and you will see a bigger image. The upper image is a top view of the brewery while the lower one sees that from the side. Why this detail? Selkirk is recording the scene just in case he wants to replicate it at his new settlement. The phases of brewing through the system are: (1) heat water in boiler; (2) mash malt with hot water dropped down from boiler; (3) draw wort off mash by gravity down into a jack tub; (4) pump or “jack” wort back up to boiler where it is boiled; (5) drop the hot wort into the first 10′ x 14′ cooler or coolship and, after some time, drop it again into the second coolship; (6) drop the cooled wort into the working tub where primary fermentation takes place; and (7) rack into barrels.

Perhaps as interesting as the idea that this might be that missing link between the Dutch wheat brewing in CNY before the Revolution and the more formal scientific brewing starting in the 1820s and ’30s is the last observation made by Selkirk. There is plenty of cider being made from trees which have re-sprouted from the roots of the orchards destroyed by the Sullivan Expedition in 1779, a very ugly campaign to eradicate the Iroquois allies of the British Crown. Their resilience then makes me wonder how long they had been growing and also if there are any descendants today.